Processing

We work to support you in your choice of products and processing methods and can offer you on-site technical assistance as well as tailor-made solutions whenever you need these. Our experts are happy to assist you.

There are already many companies that rely on us and we hope that you are also part of our large family of composites. Büfa group puts at your disposal an expertise team for assisting and guiding you to make your projects become a reality Contact us and share your needs, we will be glad to help you. Here is a first overview;

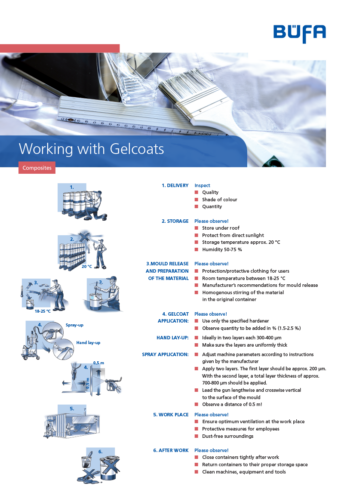

Hand lamination: Lowest investment costs, maximum freedom in component design. These are two major advantages of this process, a third: the large variety of suitable semi-finished fiber products.

Fiber spraying: In this further development of hand lamination, the material application is partially mechanized. In the case of fiber spraying, the material used is used almost without waste.

Casting: The activated resin is cast manually or by means of a dosing machine in a hollow mould where it cures and solidifies. In many cases the resins are mixed with fillers to obtain less shrinkage during cure or to save costs on raw materials.

Winding: The material, usually rovings, is passed through an impregnation bath with a reaction resin and fed via a scraper to the laying head. This places the roving on the rotating core.

Pultrusion: A continuous process for the production of bars, tubes and profiles, also called pultrusion

Vacuum Infusion: The advantage of this method over hand lamination is the higher reproducibility in terms of fiber volume content.

RTM: Resin injection process or resin transfer molding. The cost-effective process for manufacturing both sides smooth components for small and medium-sized production series.