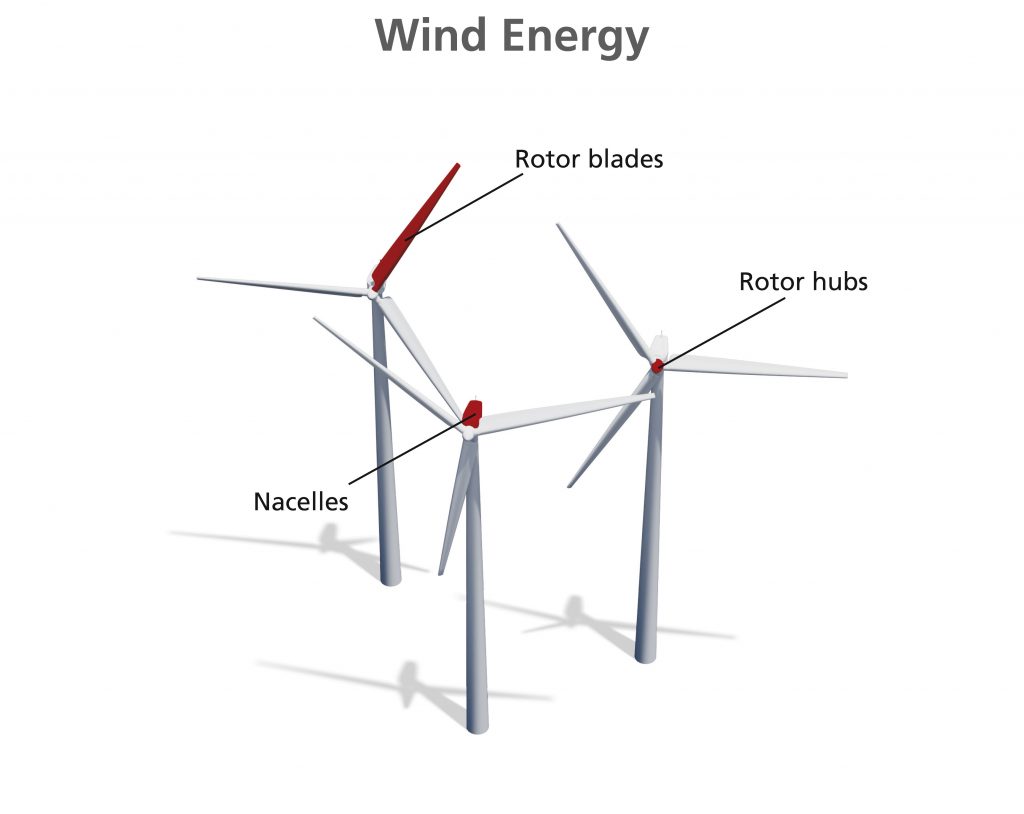

Wind energy

Continues developments in wind energy installation technology require special product of very high quality. Our range of goods includes, e.g. bonding pastes on a VE base, highly flexible LSE gelcoats, as well appropriate fire protection system.

Wind power stations contribute to the production of electric energy today to a degree that was not thought possible years ago. The required operating time of 20 years with ever increasing and especially dynamic mechanical loads when operating and, at the same time, continuously larger wind parks, make fatigue behaviour the decisive design factor when selecting materials.

The quality of a rotor blade is determined by the reliability of many bonded joints. Thick adhesive beads are needed to bond shells and stays and yet the material may not run off the sloped walls.

A gelcoat has the task of protecting rotor blades as well as machine housing from the permanent influence of weather such as moisture, light, temperature and impact loads. Highly flexible materials with good impact resistance are thus the materials of choice.

The BÜFA Composite Systems range of products includes specialities that meet the high demands on quality for this industry (e.g. bonding pastes on a VE base, highly flexible LSE gelcoats, Firestop products).