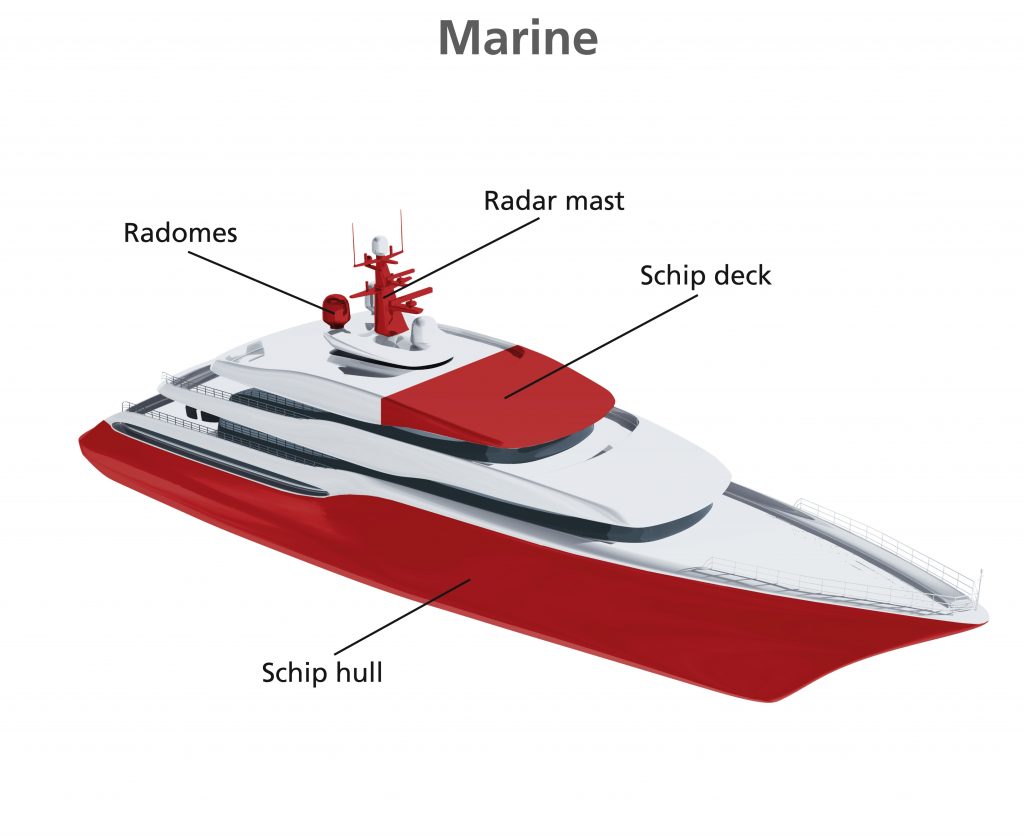

Marine

Boat Construction is an important application area for glass fiber reinforced plastics. Individual components, entire decks as well as complete ship hulls for sailing/motor yachts and power boats are produced with high quality GRP components.

This branch of industry is an important field for glass fibre reinforced plastics. Individual elements, entire decks as well as complete ship hulls for sailing/motor yachts and power boats are made of high quality fibre reinforced plastics elements. Because they must withstand permanent sunshine, salt water and repeated surface treatment by their owners, the quality of the gelcoats used must meet the highest quality standards. Characteristics such as colour accuracy, resistance to osmosis and surface gloss are the most important material attributes.

Along with gelcoat and topcoat qualities on an ISO/NPG and ISO base, BÜFA Composite Systems also has a wide range of high quality bonding pastes in their programme. These include high quality VE bonding pastes (e.g. for bonding hulls and decks), bonding pastes for sandwich constructions (e.g. for bonding foams, balsa wood), bonding pastes for universal use (for bonding wood, metal, fibre reinforced plastics) as well as very special solutions e.g. “liquid glass mats”, to prevent air from being entrapped behind the gelcoat.

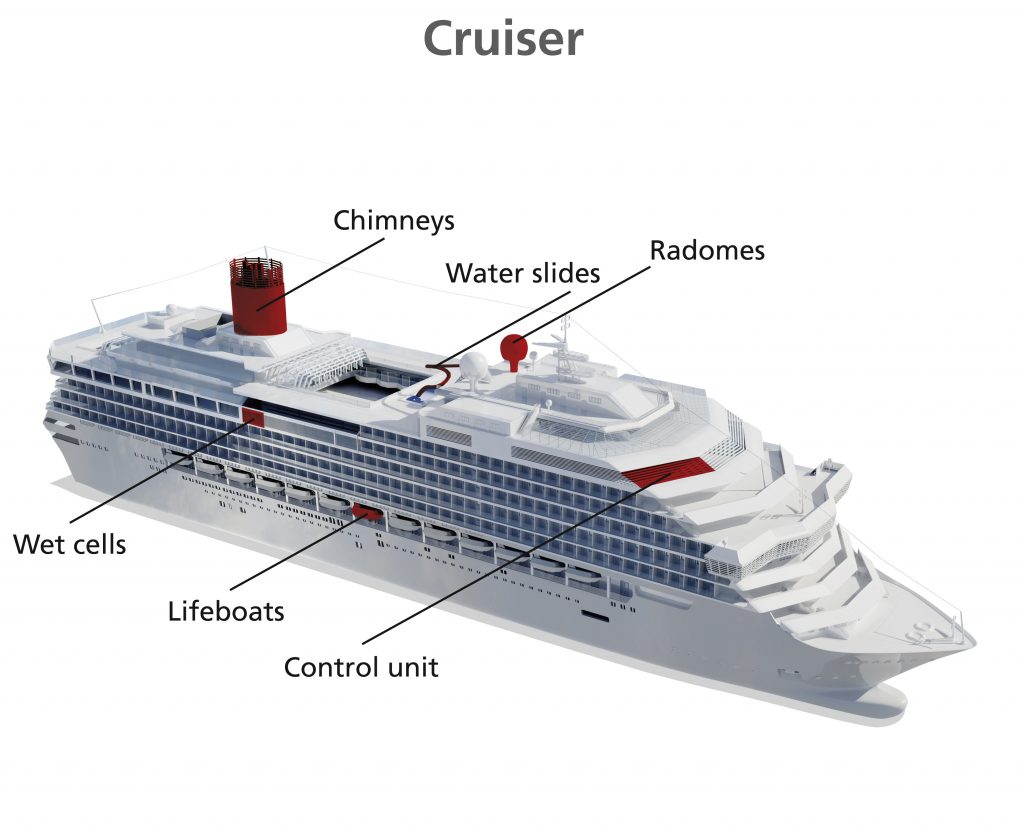

Cruiser

In the area of passenger transport on cruise liners, safety by fire protection on the highest level and the topic of lightweight construction plays an increasingly important role.With the products of our complete range, we offer solutions for the interior and exterior construction of cruise liners, eg. for lifeboats, shower cabins, sanitary cells and in the leisure area (water slides, pools and rocky landscapes).

An extensive range of BÜFA®-Firestop products (gelcoats, topcoats, bonding pastes, special resins, special products) as well as extensive know how is available for material requirements such as ignitability, flame propagation, smoke-gas development or toxicity of fumes.